Selecting a Suitable Aircraft

When FleetCaptain selects a plane for assignment, that plane has been analyzed and found fully compliant:

• The plane is available, not already dispatched, not in maintenance etc.

• There are no timed maintenance items due and none will become due during the flight *

• There are no calendar maintenance items due and none will become due during the time the aircraft is dispatched

• The plane has enough fuel to satisfy the requirements of the flight (or the first flight if a series of flights are intended)

• The plane is loaded safely, including the category for the intended flight operation

• The baggage rules have been respected

• There are no unhanded defects

• There is no conflict with a future embargo, where the plane is needed for a specific purpose

* A pilot intending a series of successive flights of unknown duration will have to verify the time remaining is suitable for each intended flight.

FleetCaptain makes this assessment for each plane in the fleet and picks the best compliant plane. It’s done instantly and revised each time the dispatcher changes any of the mission data.

Certainty Leads to Safety

There is no doubt about any of the dispatch conditions, and no doubt that the pilot has all the required information. Everything is summarized by FleetCaptain and signed off on the flight authority form. Key data includes

• Instructor and student lesson plan

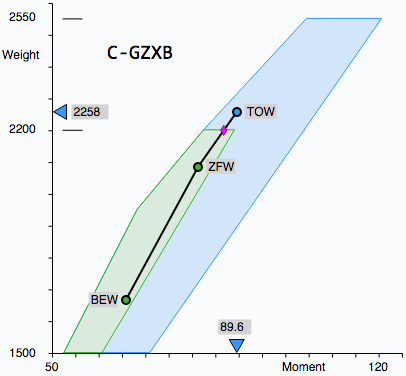

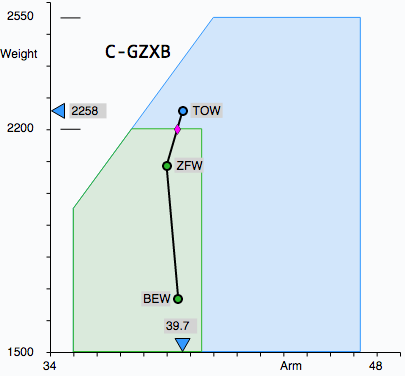

• Weight and balance chart

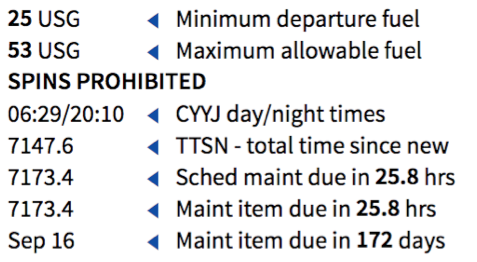

• Minimum departure fuel

• Maximum allowable fuel

• Utility category fuel and spin prohibition

• Maintenance requirements (nearest timed and calendar items)

• Defect description

• End of civil twilight

With little effort and no wasted time, the pilot’s credentials are checked, the mission and aircraft verified and the pilot is signed out. It’s all done in a moment.

Weight and Balance

A standard weight and balance chart is used to verify at a glance that the aircraft is properly loaded. FleetCaptain knows the fuel on board, knows the intended load and knows the intended flight time. With that, a minimum departure fuel and maximum allowable fuel are calculated and displayed. Normally these form a wide range of allowable fuel levels. The pilot’s job during the pre-flight is to verify the aircraft’s actual fuel is safely between the minimum and maximum allowable levels.

The vast majority of time, FleetCaptain has assigned a plane having correct known or estimated fuel, and the pilot verifies all is OK and proceeds without exception. If the aircraft is loaded such that there is a utility category of operation, this will be shown by a green utility category envelope, otherwise only the normal category will be shown along with a “SPINS PROHIBITED” reminder. The weight and balance is shown with basic empty weight (BEW), zero fuel weight (ZFW) and takeoff weight (TOW) marked on the chart. The chart is displayed either using the moment or the arm format, as desired by the pilot. If the aircraft will transition from the normal category to the utility category as fuel is burned, that will be shown graphically and the fuel level where this transition occurs is noted on the flight authority form.

No Doubt Data

The pilot needs to verify that the fuel level is somewhere between 25 and 53 gallons. Spins are prohibited. Local night begins at 20:10 today. The aircraft has 7147.6 hours on it. Scheduled and timed maintenance are both due at 7173.4 hours, 25.8 hours from now. A calendar-based maintenance item is due on Sept 16th, 172 days from now.

No turning pages. No guessing. No cutting corners. It’s all there – every flight. The pilot is not hurried or stressed. Both the pilot and the dispatcher have the luxury to manage the pre-flight process, not react to exceptions.

No one leaves over gross weight. No one conducts a spin without certainty of operating in the utility category. Maintenance and defect rules are applied rigourously. Recreational pilots are equipped to operate like professional pilots – every flight.

Softer Considerations

Safety happens when processes go well. More to the point, safety happens when nothing goes too far wrong. A snag process with no compromises. Equipment that’s repaired as soon as a fault is found. Maintenance, dispatch, and flight line staff who are comfortable, evenly loaded and clear in the performance of their jobs. Newer equipment. On-time operations. Less waiting. The pilot enjoys a relaxed environment at the counter and leaves without being burdened by calculations or hurried or delayed.

None of these are silver bullets for safety. But each tends to pull in the right direction. Every flight, every day, each process runs as smoothly and as exception-free as possible. People can focus their attention on the few issues that do arise and apply good SMS principles to dealing with them.

The team works together to anticipate and deal with risks. FleetCaptain strives to make safer operation easy, because the price of failure is high.